Need your tanks inspected? We service scuba tanks, paintball tanks and much more including visuals and hydros!

TANK SERVICE

Dive Right In Scuba is your trusted source for comprehensive tank inspections. Our expert team, with over 20 years of experience, specializes in visual and hydro inspections for scuba, paintball, and various other types of tanks. We prioritize your safety, ensuring your tanks meet all industry standards and regulations.

With a proven track record of over 1,000 inspections annually, our certified and advanced gas blenders are dedicated to keeping your dive gear in top condition. Dive confidently knowing your tanks have been thoroughly examined by Dive Right In Scuba.

Easy Steps for You

Get Your Scuba Tank Serviced at Dive Right In Scuba in Just 4 Easy Steps

-

Drop Off & Preliminary Check: Bring your tank to either Dive Right In Scuba location for an initial inspection (exterior check and hydro record review) *Pro Tip: For older tanks, call or email photos of the tank markings to check eligibility before you visit.

-

Inspection, Testing, & Repairs: We'll thoroughly inspect your tank and provide a quote for any necessary testing or repairs. Once approved, we'll complete the work within 1-2 weeks.

-

Free Air Fill or Discounted Gas: Enjoy a free tank air fill or discounted rates on nitrox or oxygen as a thank you for choosing our service.

-

Pickup & Payment: We'll notify you when your tank is ready. Simply pay for the service when you pick up your tanks.

Tank Service Pricing Guide

Check out the pricing details below and find the ideal service tailored to your requirements

Visual Tank Inspection

Visual Tank Inspection

Scuba tanks require an annual Visual Inspection, which encompasses a thorough check, air fill, and O-Ring replacement. Our certified tank technicians inspect your tank to ensure it meets Technical Diving International (TDI), Pressure Systems International (PSI), Compressed Gas Association (CGA), and Occupational Safety and Health Administration (OSHA) standards.

Other Essentials

Visual Tank Inspection

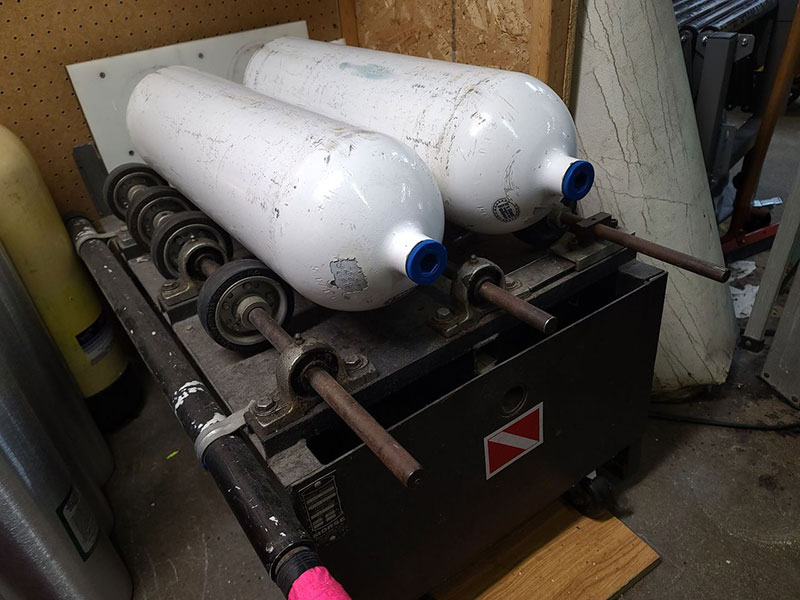

Additional Service: Doubles Breakdown and Reassemble

Assembled doubles for Visual Inspection or Hydrostatic Testing will be disassembled for the tests and reassembled after the tests are completed. *To avoid this additional service charge, bring your doubles disassembled for the service. We will refill after your reassembly.

Visual Eddy Current Test

Visual Eddy Current Test

Visual Eddy Current tests are mandatory for aluminum tanks produced before 1990. This procedure involves passing a low electrical charge through the tank's threads to assess their integrity. If required, we'll conduct this test alongside the hydrostatic test to guarantee thorough examination and compliance.

Visual Eddy Current Test

Free New O-rings

Hydrostatic Testing

Hydrostatic Testing

The hydrostatic test is vital for detecting potential flaws that could jeopardize diver and fill station operator safety. We offer hydrostatic testing services for carbon fiber and fiber-wrapped SCBA tanks, as well as paintball tanks. This examination involves subjecting the cylinder to water and pressurization to assess its physical integrity.

Federal regulations mandate this test every five years. A passing cylinder receives a stamped date (month and year) alongside our ID number, while a failed cylinder is condemned and marked with an "X" over the serial number.

Hydrostatic Testing

Seal Sizes: Small or Standard

Hydrostatic Testing SCBA

Free New O-ring

Tank Tumble

Tank Tumble

If we discover corrosion in your aluminum tank or rust in your steel tank during our inspection, we will advise that you opt for a tank tumble. This process ensures the quality of your breathing air and helps extend the lifespan of your tank by thoroughly cleaning the interior walls using ceramic media.

Light Rust

Heavy Rust

Valve Repair

Valve Repair

We disassemble your valve, and thoroughly clean all metal parts with our sonic cleaner. Afterwards, we reassemble the valve, utilizing original manufacturer parts, and then conduct comprehensive function tests to ensure peak performance and reliability.