Description

Ti 3000 and Ti 5000 Drysuits by Seasoft

SEASOFT Ti 3000™ and SEASOFT Ti 5000™ Drysuits

Many divers consider the SEASOFT Ti 3000™ and SEASOFT Ti 5000™ Drysuits to be SEASOFT’s best drysuits. If you need a really warm, compressed neoprene drysuit that can take anything you can throw at it and a drysuit you can dive with a re-breather to deeper depths, then the SEASOFT Ti 3000™ and SEASOFT Ti 5000™ Drysuits are what you want.

Here is why their owners love them; they are:

- Made of 3.5 mm (Ti 3000) or 5 mm (Ti 5000) compressed neoprene. True compressed neoprene is “chemically compressed” which means that the air cells “shrink” as the neoprene cools when it is manufactured. This causes the membrane walls around the air cells to be “thicker” or stronger. These reinforced air cell walls are now more resistant to the external forces of pressure and less likely to compress as much as regular neoprene under that pressure. Due to this resistance to compression the SEASOFT Ti 3000™ and SEASOFT Ti 5000™ can be safely dove to greater depths. They are rated to a depth of 350 feet (107 meters), which makes them advantageous for re-breather divers who are trained and certified to dive to these depth.

- Manufactured with an external surface of DINA-HIDE™, a very tough, abrasion-resistant mix of tightly woven polyester and nylon. This 1.5 mm material adds an extra layer of insulation to your drysuit. This extra-tough material makes these drysuits well suited to shipwreck and cave diving because they can stand up to the constant abrasion and abuse this type of diving delivers.

- Warm! Very, very warm! Here is the phrase we hear over and over again, especially in describing the SEASOFT Ti 5000™; “This is the first time I have ever been warm diving!” We hear this because with the combination of compressed neoprene, the TITANIUM FLAKE FOIL™ Technology, and the DINA-HIDE™, the SEASOFT Ti 3000 and SEASOFT Ti 5000™ are the warmest drysuits available anywhere.

If you want the warmest, toughest, “dives the deepest” drysuit then these drysuits may be the perfect for you!

SEASOFT DRYSUITS - The Drysuits Divers Covet

For nearly two decades SEASOFT Drysuits have been considered the best neoprene drysuits. That’s because every SEASOFT Drysuit is hand cut – one at a time! Then each component is hand glued, using the dive industry’s most advanced glues. Putting a drysuit together is as much art as it is science; here is how it is done.

When you cut neoprene, you can see that you have cut through tiny air bubbles on the cut edge; there are actually millions of them. When you craft a drysuit, the first thing that must be done is to block these bubbles as potential sources of a seam leak.

Special glue must be applied to the edges of the neoprene to cover the bubbles and allow for the two edges to eventually be glued together. This process is referred to as a “build up”. When this first layer of glue dries, a second layer of glue is applied. After this layer dries a third layer of drysuit glue is applied. At just the right moment of tackiness, when both sides are at the right consistency, they are joined together to create a waterproof seal that will bond them together for life.

The outer seams are reinforced by “blind stitching” them. Unlike a typical sewing machine that utilizes a needle moving up and down, blindstitching is done with a special machine that actually stitches sideways across the fabric pulling the two seams together.

Next, each section of the drysuit is turned inside out and the seams are coated with a special “wet” glue that penetrates the fabric creating another waterproof barrier as well as reinforcing the seams. After drying, a thicker glue is applied to this first layer to reinforce the seams again. A third layer is applied to give the seams their final reinforcement to create a lifetime of dryness.

While the sections were being assembled, the following were installed:

• STRETCHTEX™ wrist seals • SHARKSKIN Kneepads™

• STRETCHTEX™ neck seal • SEASOFT Suspender System

• STEALTH™ boots • Si-Tech Valves

• YKK™ or Ti Zip SUPERSEAL™ waterproof zipper

The drysuit sections are then pieced together to make the final suit. The gluing and reinforcing processes are then repeated for these seams. You can see the hours that go into making a hand crafted SEASOFT suit dry and comfortable.

SEASOFT DRYSUIT ZIPPERS

SEASOFT uses either YKK™ brass zippers or the Ti ZIP SUPERSEAL™ dry zipper for their drysuits.

1. YKK™ Brass Zippers - YKK™ has been around for a long time and they are almost synonymous for “zipper”. YKK™ brass zippers have long been the standard for commercial drysuits.

2. Ti ZIP SUPERSEAL™ - Ti ZIP™’s SUPERSEAL™ drysuit zipper, manufactured by a German company, allows a diver to:

A. Traditionally install the zipper along the back.

B. Use a lighter and more flexible zipper than a traditional brass one.

C. Easily zip and unzip yourself in and out of your drysuit.

This last one is unique because being able to don and doff your own drysuit in a matter of

seconds is not only convenient but can be crucial in an emergency, hot weather, when you have to “go”, and other situations.

STRETCHTEX™ Wrist and Neck Seals

STRETCHTEX™ is a special 3.5 mm neoprene used by SEASOFT for its neck and wrist seals. Why are these seals superior to latex? They’re:

- Warmer. Latex has no thermal protection while STRETCHTEX™ has 3.5 mm of warmth built in.

- More reliable and economical. Latex easily tears. STRETCHTEX™ has a nylon backing so it can easily be repaired, even in the field, and they typically lasts for years vs. latex that is often repeatedly replaced.

- Much more comfortable. Latex relies on constriction to keep the diver dry. STRETCHTEX™ relies on the air inside the folded neoprene trying to escape, this creates a firm but gentle pressure against the diver’s neck and wrist to create a watertight seal.

SEASOFT Suspenders

SEASOFT has one of the most comfortable and functional suspender systems. SEASOFT attaches 4 tabs to the inside of the suit. The fully adjustable suspender system attaches to the tabs with 4 flat side release buckles so it can be removed if desired. The system is mounted high so that when the top is released and hangs down the arms do not contact the ground. As usual, all the little details are well thought out.

STEALTH BOOTIES™

SEASOFT is famous as the only company that makes wetsuit booties that are fully athletic with an elevated heel and built in orthotics. SEASOFT has brought this same technology to its drysuits. SEASOFT developed a drysuit version of its STEALTH Booties.

You will be diving with at least a hundred pounds of gear while wearing your drysuit. “Should you be diving with athletic footwear or a bedroom slipper?” The obvious answer is athletic footwear. SEASOFT makes the ONLY athletic drysuit bootie because details matter.

SI-TECH VALVES

SI-TECH drysuit valves from Sweden are internationally accepted as the leading manufacturer of valves for drysuits; we use them because they are the best.

SHARKSKIN Kneepads™

The SHARKSKIN Kneepads™ may be the best in the dive business. This super tough, abrasion resistant material is already molded to a neoprene backing so it does not require the extra padding that others add to their suits. This takes two layers down to one reducing the chances of a kneepad failure.

THE SEASOFT DRYSUIT PATTERN

The first SEASOFT Drysuits were manufactured almost two decades ago and from the beginning Bruce Justinen, the designer of SEASOFT’s drysuit, asked, “If I was only making one drysuit, and that drysuit was for me, how would I make it?”

How would you make your drysuit? Would you cut corners? Would you try to save a few pennies here or there or would you want the best technology and the finest materials?

Here is how we make a drysuit, we cut the front and back of all SEASOFT Drysuits out of one piece of neoprene – no seam in the crotch. Would you put a seam in the crotch of your drysuit by cutting two pieces of neoprene to save money? NO? We don’t either!

SEASOFT puts “raglan sleeves” on all its drysuits; this sleeve is wider where it attaches to the drysuit torso. This wide sleeve:

1. Makes it extremely easy to don and doff.

2. Eliminates leaks under the arms; the seams are no longer under pressure when you move your arms.

3. Gives the diver extraordinary freedom of movement.

4. Is like a funnel and allows all the air to move to the exhaust valve mounted on the upper forearm. This banishes air approximately five times faster than a shoulder-mounted exhaust valve for fast, efficient release of air.

5. Lets a new drysuit diver learn buoyancy control in minutes. Even a diehard user of a shoulder mounted dump valve will quickly realize how superior it is.

SEASOFT Drysuits are made with up to 60% fewer seams than other drysuits; fewer seams means a longer, drier life for you and your drysuit. Why not discover what so many others have, SEASOFT Drysuits are logically better!

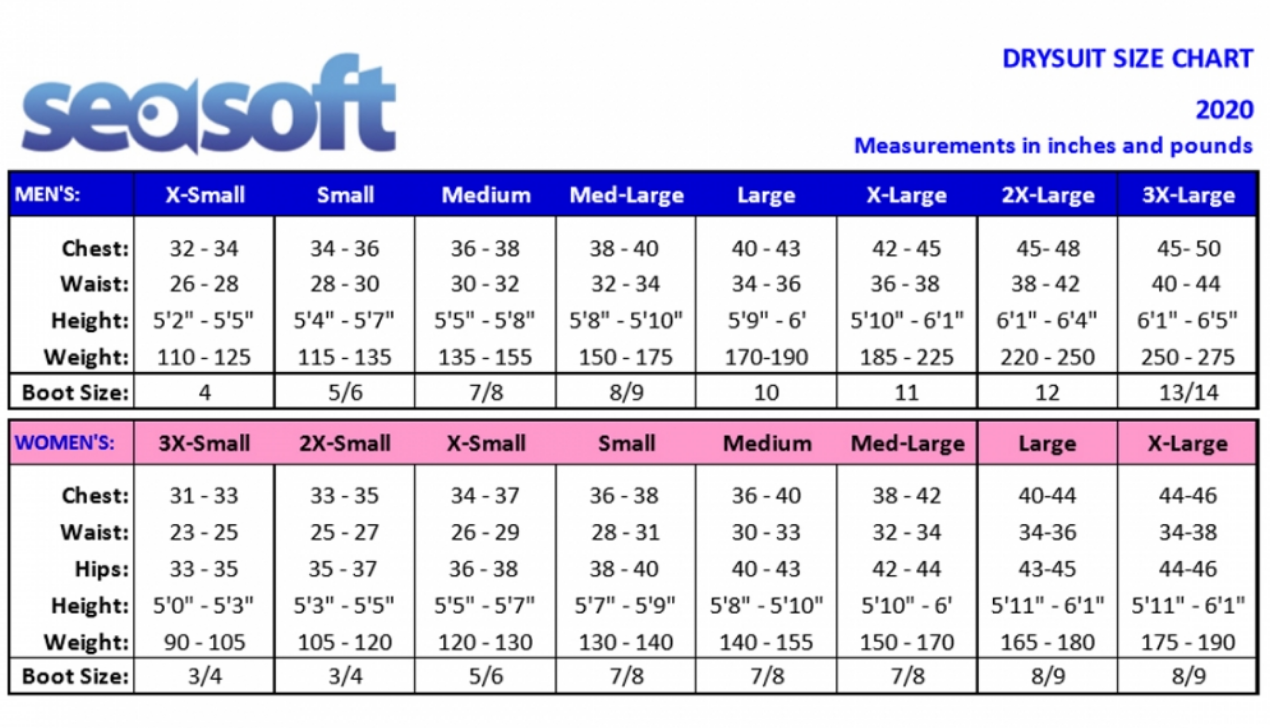

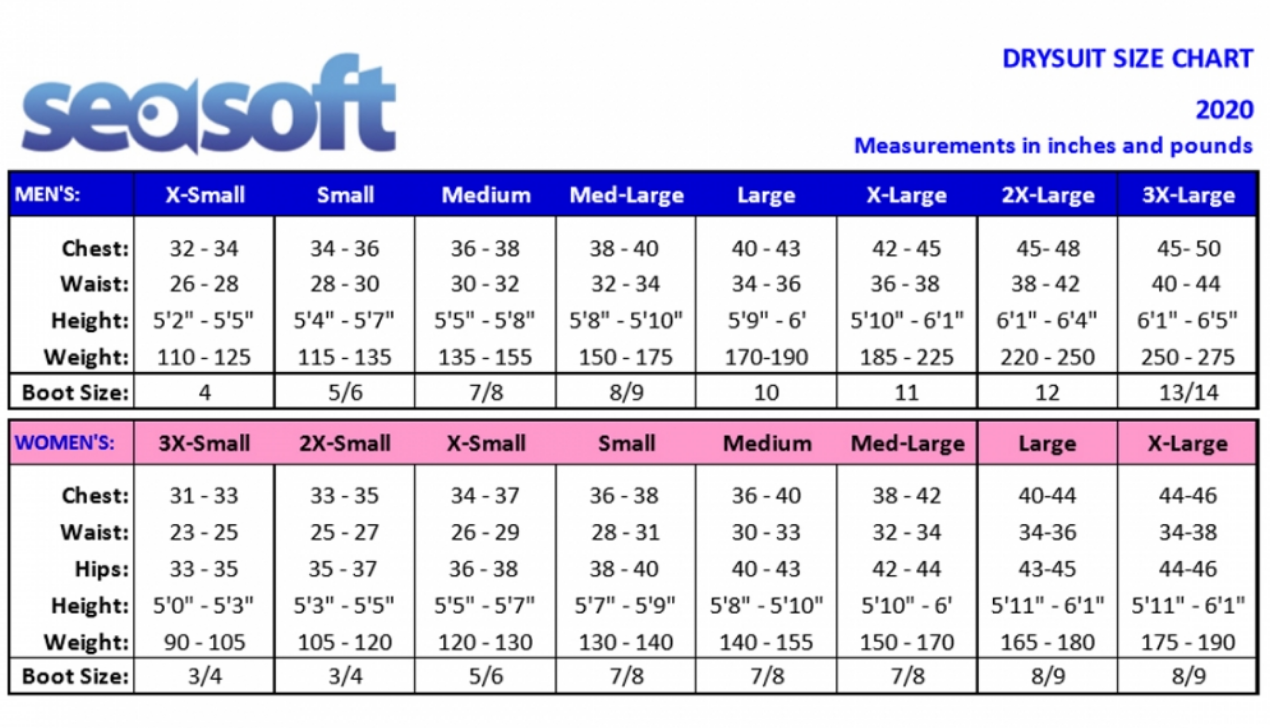

Size Chart

Size Chart

Female Size Chart

Reviews

Product Q&A

Easy Returns

60-Day Hassle-Free Returns

Not the perfect fit? No problem. We offer a 100% credit or refund on any item returned within 60 days, as long as it's in new, unused condition with its original packaging. We want you to be happy with your gear, period.

Click here for more info100% Secure Shopping

Order With Confidence

Your security is our top priority. We use the latest encryption technology to ensure your personal information is 100% safe, so you can shop with total peace of mind. Not comfortable ordering online? Give us a call at (815) 267-8400 and we'll gladly help you over the phone.

Full Manufacturer's Warranty

Authorized Retailer for Seasoft

We are an Authorized Dealer for every single brand we sell. This means you are getting 100% authentic gear, and your purchase is fully protected by the manufacturer's warranty. No gray-market gear, no warranty worries. We've got your back.

Our Promise to You

We\’re Divers, Just Like You

Our promise is that you get the right gear, and that it's right the first time. As divers ourselves, we'll help you find the perfect fit for your style of diving. Then, we'll quality-inspect your order before it ships to ensure it's ready for your next adventure. We're your local dive shop, no matter where you are.

Proposition 65

Safe Water and Toxic Enforcement Act of 1986 – Warnings Required

WARNING: This Dive Right In Scuba product can expose you to certain chemicals which are known to the State of California to cause cancer, birth defects, or other reproductive harm. For more information go to www.P65Warnings.ca.gov

We appreciate your decision to purchase Dive Right In Scuba products to provide the best in water experience. We take our job seriously! You may have noticed that our products now show a warning label at point of sale referring to carcinogens and birth defects. You may also have begun to see warnings related to carcinogenic substances or substances causing birth defects prominently displayed in hotel lobbies, hospitals, or other places of business recently. These warnings are required by the State of California, and we believe that an explanation of the California statute legislating the requirement will provide you valuable information regarding the relative risks of the chemicals that may be present in consumer products.

In 1986, the State of California passed the Safe Drinking Water and Toxic Enforcement Act; otherwise known as “Proposition 65” or "Prop 65". Prop 65 requires businesses like ours to disclose to individuals the presence of chemicals listed in the Act prior to point of sale. The regulations implementing this Act have been amended over time with the most recent updates will take effect on August 30, 2018. There are more than 900 chemicals on the Prop 65 Chemical List, including many chemicals that are found in components of a wide array of consumer goods or are used to manufacture components that make up consumer goods.

Prop 65 does not establish acceptable concentrations for any listed chemical; however, the agency which enforces it has established what is called "safe harbor" exposure levels for about one third of these chemicals below which warnings are not required. These "safe harbor" are established for listed carcinogens based on the quantity of the chemical that would result in one excess case of cancer in an exposed population of 100,000, assuming lifetime (70-year) exposure at the level in question. A similar process is used to establish safe harbor levels for listed reproductive toxicants. Additional information in plain language on safe harbor levels is available from the California Office of Environmental Health Hazard Assessment at http://oehha.ca.gov/Prop65/background/p65plain.html

At Dive Right In Scuba, the safety of your in water experience is our highest priority. We go to great effort to select materials that offer superior value, quality, and durability while also being generally recognized as safe and reliable for the full life of the product. Dive Right In Scuba also works closely with many regulatory bodies, such as the US Coast Guard and Underwriter’s Laboratories, to ensure the longevity of your on-water safety through targeted selection of durable, long lasting materials and components that undergo significant validation testing before being used to manufacture end items. Sometimes the safety promise we offer appears at odds with the health and safety requirements of other legislation in certain parts of the world when some regulations are updated ahead of others. To ensure compliance with applicable legal requirements, Dive Right In Scuba has placed a warning on products that contain a Prop 65 listed chemical, either directly or as a part of the raw material supply chain. This allows us to comply with California law and provide our California consumers with the disclosure required by Prop 65, while still promising the safest on water experience possible.

Dive Right In Scuba is working diligently with regulatory bodies and our own manufacturing partners to continue to continue to improve our product performance and reduce the presence of less desirable chemicals. Water is a precious resource we all share that is important to the health and well-being of our planet and all people. Our goal is to continue to enhance your water life experience while reducing our overall impact to the planet and, in particular, its waterways. While it is a bit of a juggling act to achieve, we are confident you will see continued improvement in both the immediate and long term future. We hope this explanation will enable you to understand why you will be seeing warnings on some our products.

Thank you for your continued use of Dive Right In Scuba products.